Here below are some factors that would cause the iphone battery bulge.

Firstly, We will analyze according to the appearance. If the appearance is deformed and it can be judged from the surface of the battery and the four corners of the battery. Most of the concave places are when the battery is dropped or squeezed. There is a micro short circuit inside the battery, which will gradually cause bulging imagination.

Secondly , when you installing the battery with wrong cooperation that your nails are pressed the battery So that the battery is squeezed and which is the another factor to make battery bubble.

Thirdly, it will be the shipment factor. Because the battery cell is Li-polymer and very soft material , but the shipping company don’t know how to take care of the cargoes that they treat the goods with rude way and make the battery damaged and also can cause bubble slowly .

Lastly, it may the battery cell that we can not test whether the inner battery cell with air and moisture inside, which will be the technology problem and will be the batch problem , but if not the whole order has such bubble problem , so that the factor can be excluded .

Last but not at least, all the battery cell we will make them aging test , when before producing , and also will come into the functions of the battery cell, like internal resistance, voltage, current and capacity and ect. And the same as PCB also 100% tested (charging , discharging, internal resistance, voltage, current, capacity and ect) before production.

After finished connecting PCB and battery cell , there is another testing step for semi-finished products , same as testing their all functions(charging , discharging, internal resistance, voltage, current, capacity and ect).

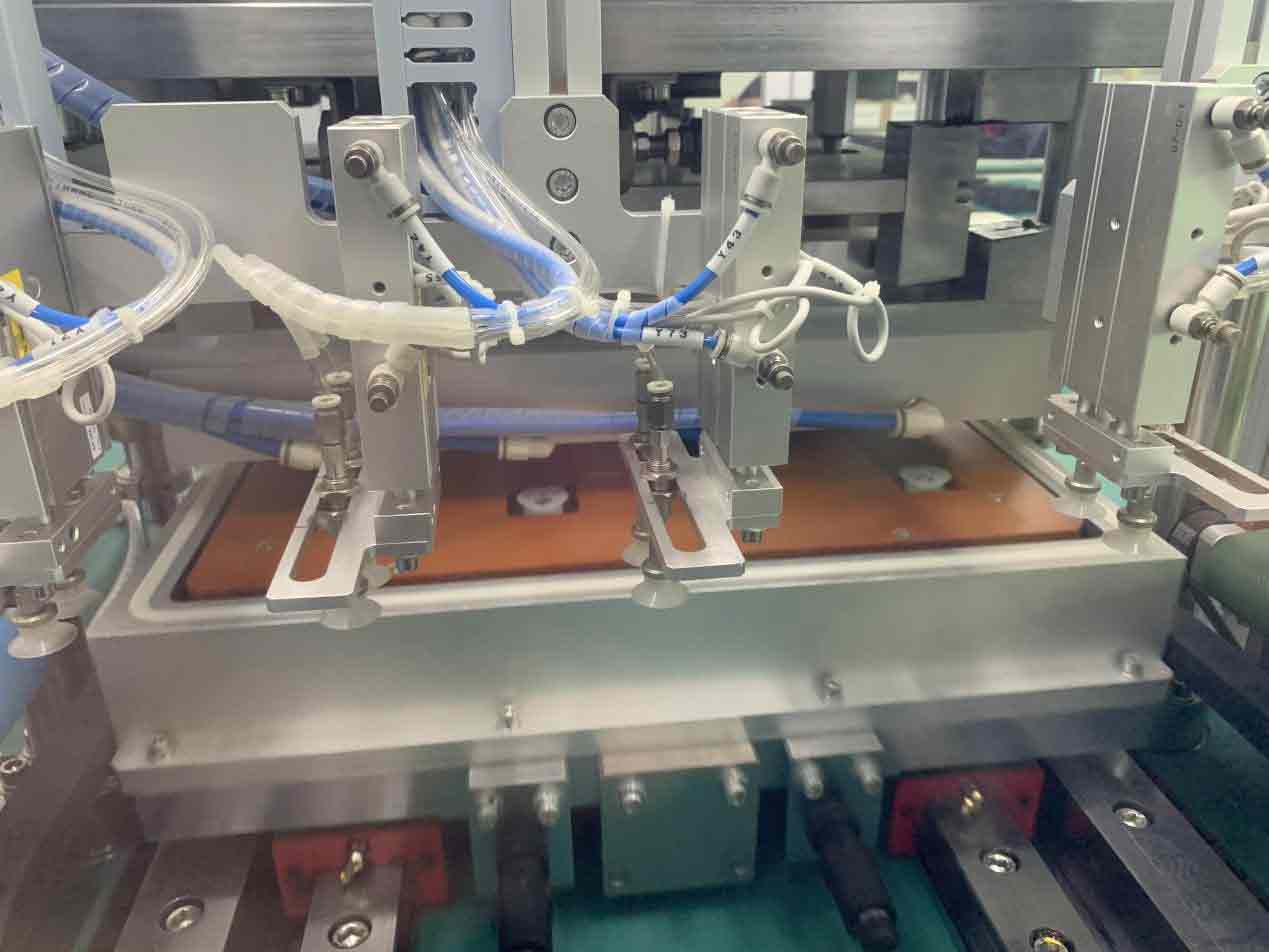

The last but the most important , glad to let you know that we added quality improvement. Please check attached photos.

This is the advanced testing machine in the market, called leak detection equipment by positive pressure(blowing gas), it has been in normal operation, which can effectively find the defective battery cells and the swollen batteries .

After testing all functions of the finished batteries , we will add the testing step with such testing machine to test again the battery cells before packing and the other factories still haven’t have such advanced machine in the battery industry except original Apple factory.

There are many testing procedures to make sure good quality before delivery . But as you know the iphone battery is too complicated when shipment or human factors that cause the defective products which we can not control . But we can make sure that each unit battery must be tested good quality before shipping .

We always think quality as culture that is the reason we have manufactured mobile phone battery for such long time since 2006, and also our boss is battery engineer and always strict with the quality that we can provide you good quality products and support you enlarge your business .

sales@batterydeji.com

sales@batterydeji.com